| Machine

Description |

Quantity | Delivery time | Container

Type |

Price USD

FOB TIANJIN |

| fillet welded pipe roll forming machine | 1 SET | 45 working days

after receiving deposit |

One 40 FT

Up to final design |

USD79000---249000 |

The following types fillet welded pipe roll forming machine:

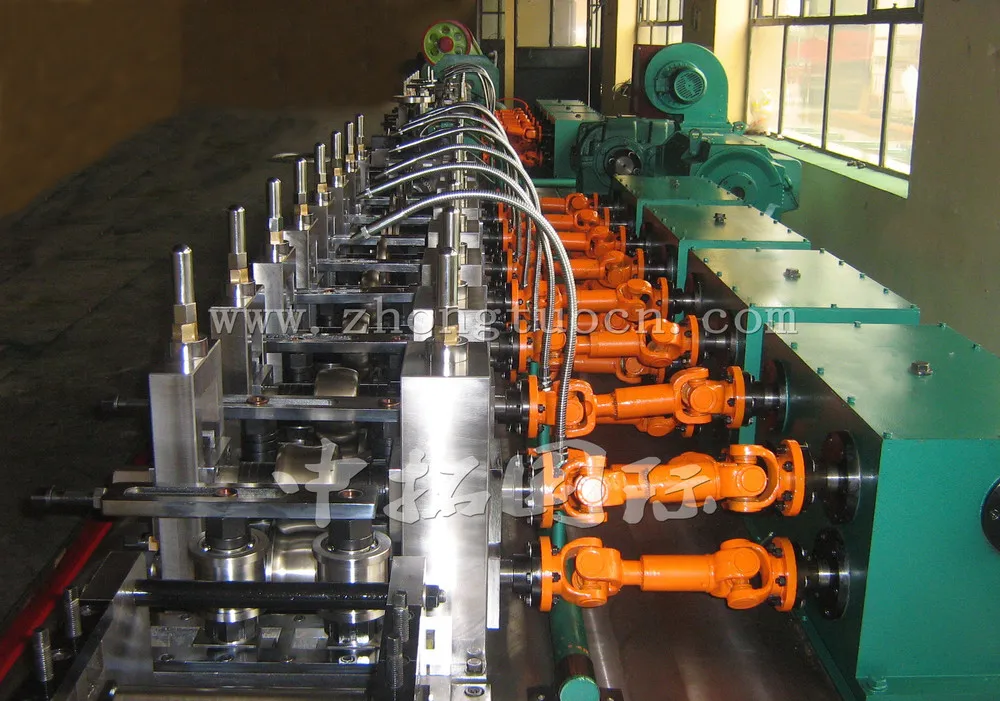

Here are some fillet welded pipe roll forming machine pictures:

Basic fillet welded pipe roll forming machine parameters:

| Main elements of fillet welded pipe roll forming machine | ||

| Name | Frame | Parameters |

| Loading car | Up coil by hydraulic power and

motored car by electric power |

Outside diameter of coil:1000-1600mm

Max coil weight:6T Car speed:6m/min |

| Decoiler | Conehead style with slider,

motored by hydraulic power to open coil with brake. |

Coil outside diameter:1000—1600mm

Max coil weight:6T Motor: 4KW Oil tank: 110mm for 500mm one time |

| Unbender

unit |

Open coil and put it to next

processor. It has four oil tanks for leveling coil, open coil, up coil and put it to feeder. |

Supported coil width:160—480mm

Coil thickness: 2.0 -5.0mm Motor:2.2KW |

| Two roll pass

coil feeder |

Send coil to cut to length machine

for getting valid width of coil and then welded coils together. AC motor, gear box transmission and power by hydraulic tank. |

Supported coil width:160-480mm

Thickness of material:2.0-5.0mm Feeding speed: 20m/min Motor: AC 11KW |

| Cut to length

machine |

Remove Irregular part of coil head

and end for welding with new coil. Dragon Gate style upper cutting. |

Supported coil width:160-480mm

Thickness of material:2.0-5.0mm Oil tank power: 10mpa |

| Platform

for welding |

Welded coil with next for nonstop

production. Double diameter cylinder for tighten coil then weld them together. |

Supported coil width:160-480mm

Thickness of material:2.0-5.0mm |

| Four-roll coil feeder | This part is for making sure there is

enough coil in the accumulator, deliver coil to the accumulator. |

Roller diameter:180mm

Rolling width:580mm Material:GCr15 Motor:YCT 30KW Speed:100m/min |

| Cage

Accumulator |

For coil stock and nonstop

production. There are four parts, fixed frame, adjustable frame, coil plate and roller for tightening coil. |

You can adjust this accumulator according

to the coil width. |

More about fillet welded pipe roll forming machine

Next: High frequency electric wiring pipe making machine