Interlocked pipe with punching holes for rails

Metal pipes made by rolling forming machine, normally has two type: welding pipes and interlocked pipe. In the article, we introduce the second interlocked pipe machine. For the normally interlocked pipe without holes, that will be easier but in this part, I will show you another type: interlock pipes with high density of punching holes.For the normal interlock pipe like rain gutter pipe, Decorative tube and other, the thickness within 1.0mm, that is easy. But the following machine I interoduce, the thickness of the materail will reach 1.2mm and sizes are quite small, so it will be quite hard to make.

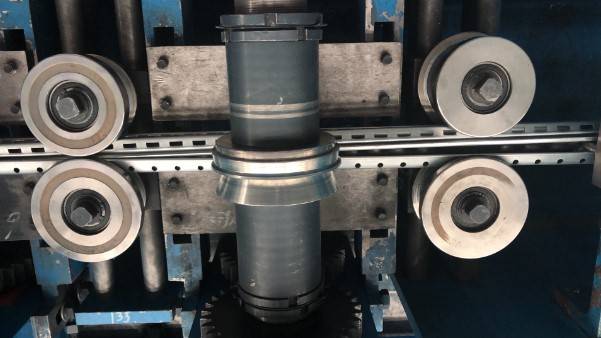

Here is one machine picture for your reference:

Metal Interlocked pipe with punching holes for rails working flow:

For making interlocked pipe with holes, we do as the following.

1. Put the narrow strip to the decoiler and then to the leveling part. As this decoiler, you can either choose the manual decoiler or hydraulic decoiler.

2. Second after leveling, by the servo coil feeder sending the materail to the punching machine and then to the main rolling forming machine.

3. To the main rolling formig machine to do the shape changing. For the main rolling forming machine, the roller pass is around 30 rollers stations to make sure the interlock pipe sizes and accuracy. As to the machine, we use the molding frame of thickness 55m, and the transmission, we use gearbox to make sure the pipe machine can work long time. For the machine, the most diffiult part is the interlocked part, there we use many vertical rollers for make sure the size, please check details in the following picture.

4. To the shearing part, we add the turkey head to make sure the accuray and then hydraulic cutting.

5. The advantage of the Metal Interlocked pipe with punching holes for rails could be used for a long time, and it can make sure the accuracy.

6. Nearly there is no any after sell problem, so it is easy to do the maintainess.

If you want to know more inforamtion, please contact us at any time.