What is HF welding tube process ?

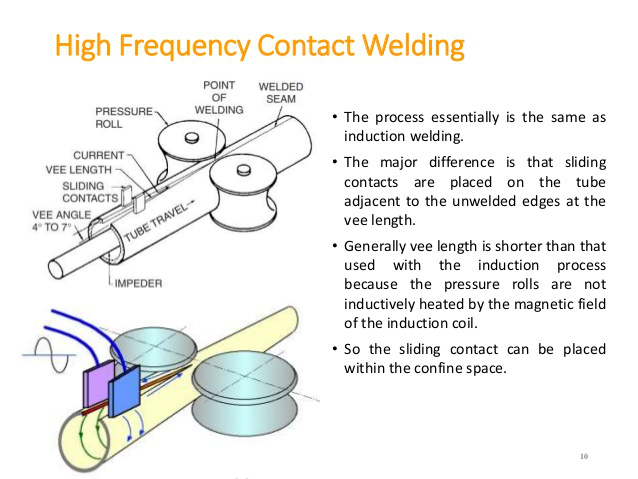

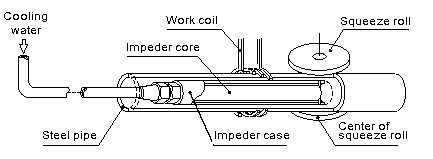

High Frequency Welding, known as Radio Frequency (RF) or Dielectric welding, is the process of fusing materials together by applying radio frequency energy to the area to be joined. The resulting weld can be as strong as the original materials. HF Welding relies on certain properties of the material being welded to cause the generation of heat in a rapidly alternating electric field. This means that only certain materials can be welded using this technique. The process involves subjecting the parts to be joined to a high frequency (most often 27.12MHz) electromagnetic field, which is normally applied between two metal bars. These bars also act as pressure applicators during heating and cooling. The dynamic electric field causes the molecules in polar thermoplastics to oscillate. Depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the material. A measure of this interaction is the loss factor, which is temperature and frequency dependent.

And then to the sizing system to finish the whole process.

Description of Precision High Frequency Welding Pipe-making Machine Line :

ZT PIPE ROLLING FORMING MACHINERY introduced the advanced technology from U.S. ,Japan and Taiwan etc., specializing in manufacturing the welded pipes of 7mm-125mm which includes the precision high-frequency tube-making welded equipment and argon-arc tube-making welded equipment covering HG16, HG20, HG32, HG50, HG76, HG114, HG127 and Max HG165. Our products have been used and gotten widely praised by such clients from more than 20 countries and areas as China domestically, Taiwan, Middle East and so on. Our Equipment Department has the annual capacity of more than 150 sets.

We have a team group of first-class rich experience and well-trained technicians. The welded pipe-making equipment developed and designed by ourselves meets the international standard.

Precision High Frequency Welding Pipe-making Machine Line mode:

| Equipment Type | HG16 | HG20 | HG25 | HG32 | HG45 |

| Manufacturing pipe diameter | ¢7.5-16mm | ¢10-25mm | ¢10-28mm | ¢13-38mm | ¢16-50mm |

| Manufacturing thickness | 0.3-1.0mm | 0.3-1.0mm | 0.5-1.5mm | 0.6-1.8mm | 0.7-2.0mm |

| Producing speed | 0-90m/min | 0-90m/min | 0-9.0m/min | 0-90m/min | 0-80m/min |

| Main engine power | 22kw | 37kw | 45kw | 75kw | 132kw |

| HF power | 60kw | 60kw | 100kw | 100kw | 150kw |

Why ZT MACHINEY HAS THOSE MODES:

HG16 Pipe-making machine line mainly applied in manufacturing electronic heating pipes and refrigerator pipes and suitable sizing thin-wall pipe and mainly applied in manufacturing thin-wall pipes.

As to the other types , Pipe-making machine line mainly applied in manufacturing frame-tubes and fitness equipment tubes.

Basic configuration: double-head decoiler 一 shearing butt welding(customer self-assembly) 一 looper一forming machine一high frequency welding一removing outter burrs一 sizing mill一siping and standing straightening 一computer sawing一blanking frame

Frame tube lines:

| Modes | ZY50 | ZY60 | ZY76 | ZY89 |

| Manufacturing pipe diameter | ¢20-63.5mm | ¢25-76mm | ¢32-89mm | ¢35-100mm |

| Manufacturing thickness | 0.8-2.75mm | 1.0-3.2mm | 1.2-3.75mm | 1.2-4.0mm |

| producing speed | 0-70m/min | 0-70m/min | 0-70m/min | 0-65m/min |

| Main engine power | 150kw | 180kw | 264kw | 264kw |

| Main engine power | 200kw | 250kw | 300kw | 300kw |

API pipe, pressure transmission pipeline & structural tube

| Equipment Type | ZY125 | ZY165 |

| Manufacturing pipe diameter | ¢50-130mm | ¢76-165mm |

| Manufacturing thickness | 2.0-5.0mm | 2.0-6.0mm |

| producing speed | 0-45m/min | 0-45m/min |

| Main engine power | 370kw | 400kw |

| High frequency power | 400kw | 500kw |

Next: Economic slow speed TIG steel pipe welding machine/ TIG pipe welding machine