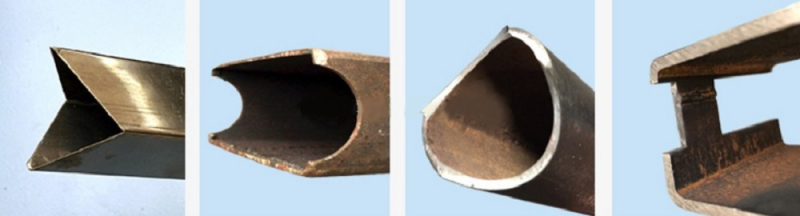

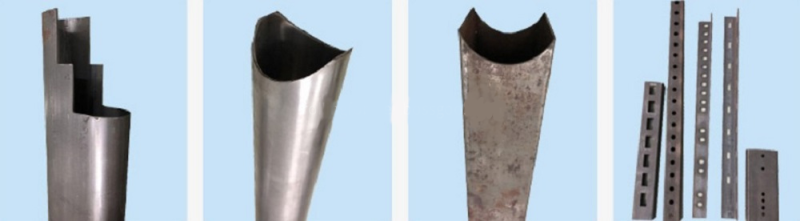

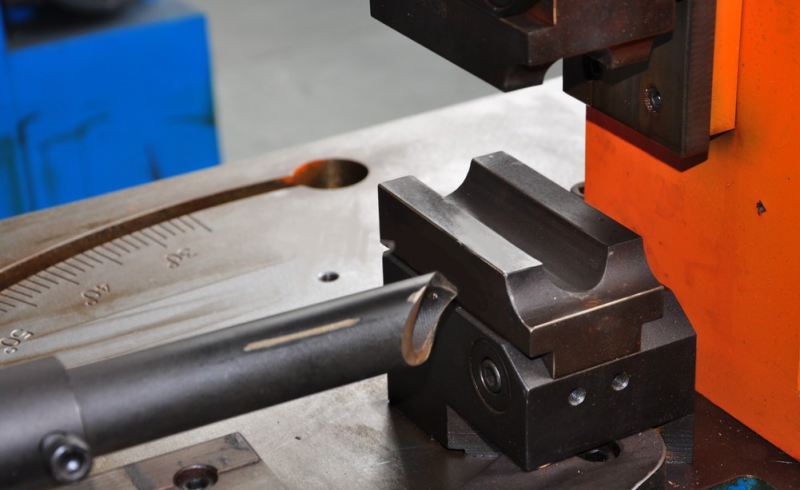

The Hydraulic metal tube hole punching machine Hydraulic metal tube hole punching machine is a customized multicylinders punch machine. metal hole punch machine is widely used to punch steel tube, stainless steel tube, iron pipe, aluminum alloy,aluminum window and door frame,copper tube,GI C Purline, Metal angle and so on. The holes shapes of tube punching can be round holes, square holes rectangle holes and oval holes.

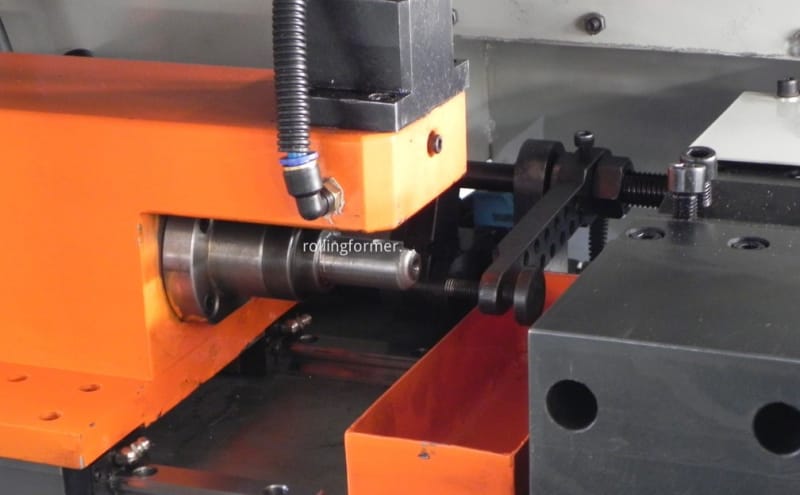

There are manual tube hole punching machine and full automatic tube hole punching machine. The tube hole punching machine is driven by hydraulic power, manual feeding steel pipe by workers. The tube/profile holes punching machine can be customized design according to customer's requirements. The molds can be changed to achieve different types hole punching working in one set machine just through adjusting or changing the punching molds.

Machine characterics features:

1 Automatic CNC punching machine is powerful and suitable for punching various metal materials such as pipes and plates. It can be customized according to the needs of customers. High efficiency, high precision, and more labor saving.

2 Famous servo brand, the servo motor stability is high, and high precision,finishing the holes in exactly sizes.

3 User-friendly human-computer interaction screen is easy to understand. Built-in memory function to store multiple sets of data.

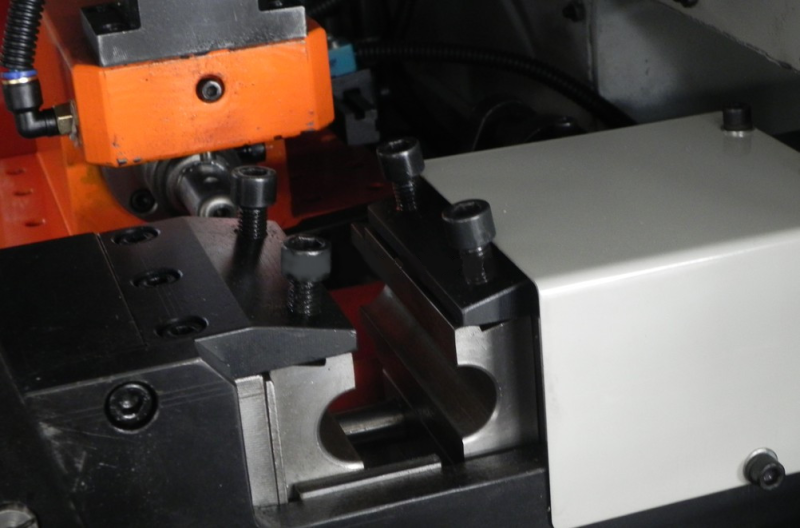

4 Machine frame is heavy and with thick metal to avoid the Error caused by machine vibration.

5 Mold is designed in the thought of 100% safety, Using the importing DC53,W6 metal materia, More durable, smooth and burr-free.

6 Professional team to support the after sale, the installation,the training and so on.

Machine specifications:

Hydraulic oil tank standard:R0100-R0200

Oil working processing:100-200

Machine Controlling system: PLC touch screen controlling

Machine voltage: Common 380V/50HZ or be customized according to requirement.

Maximum material length: 6000mm

Servo motor power:750-2000

Maximum feeding speed:800mm/s

Precision: ±0.1

Power:5.5-18.5KW

Processing Thickness:0.5-14mm

Clamping type:Hydraulic clamping system

Feeding and receiving:Manual

Machine size:7100x800x1650

Machine wight:1300-2500Kg

How to get an inquiry from us:

Every friends, thank you so much for your reading!

If you need more information about our tube bending machine, please feel free contact me please!

Also if you want to order one tube bender machine, please kindly send me your detailed information to me. we will design the machine for you.

Before we make the full solution for you, we need below information tube parameter from you:

1. Tube material

2. Tube diameter

3. Tube holes or arc end shapes, if possible do you have a frawing or picture to send to us.

4. Do you need other related tube processing machine, such as: Tube cutting machine, Tube chamfering machine, Tube punching machine, Tube end forming machine.

welcome sending me an inquiry now!

Next: Single head arc punching machine Tube notching Machine